Best quality Corrugated Board Production Line - Grain bin silo leg making machine – Thomas

Best quality Corrugated Board Production Line - Grain bin silo leg making machine – Thomas Detail:

Silo Silo upright production line : Storage silo manufacturers know that punch accuracy and minimal flare are critical in Silo column , and so do we. That’s why we offer a variety of robust, accurate silo post line solutions to handle product ranging from different thickness. Mechanical and hydraulic pre and post-punch / cut designs mean we can provide a solution to nearly every stiffener manufacturing scenario. While options like rafting, inline splice production, and download capability maximize system utilization and profitability.

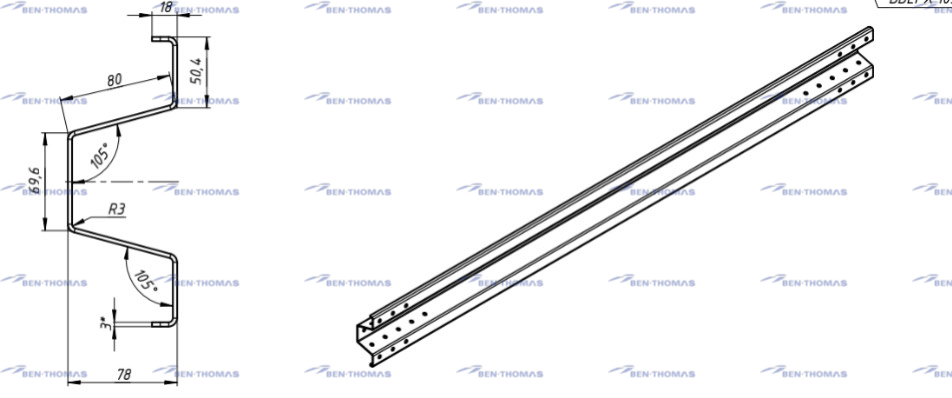

1.Drawing of the profile of the silo stiffener:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

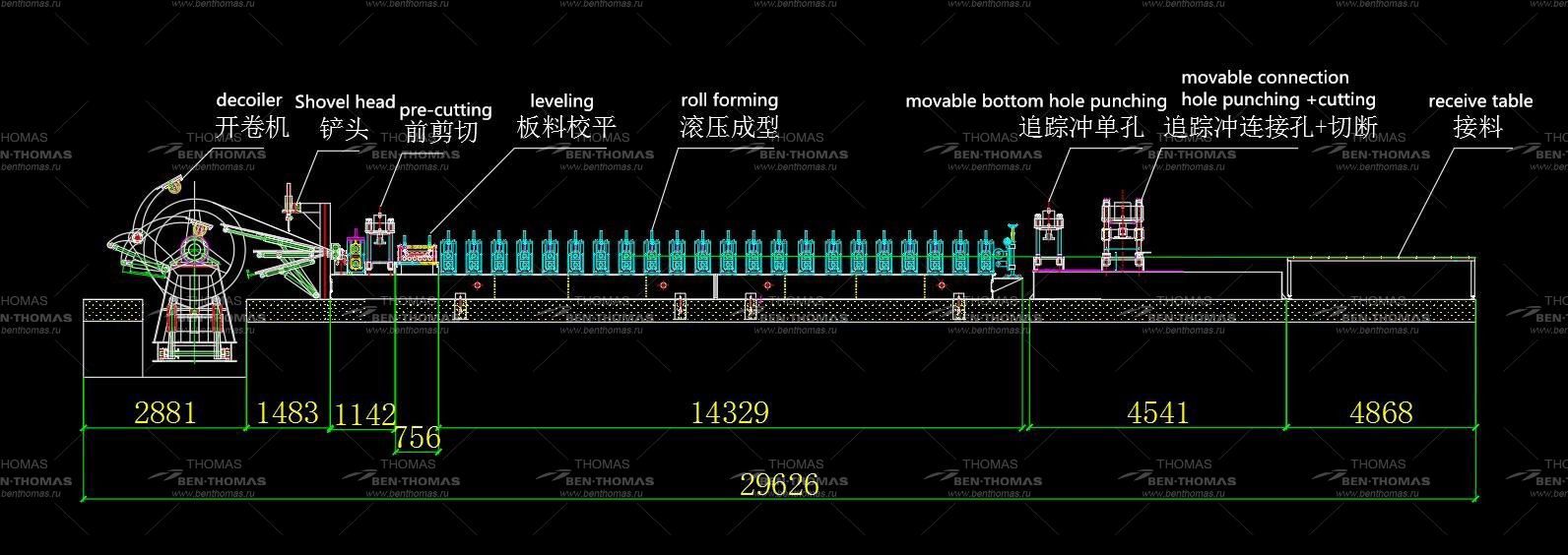

3.Working process of the production line:

Hydraulic decoiler –Shovel head device(Auxiliary feeding +Leveling) –Pre Cutting–Roll Forming Machine–Slitting & Waste Wire Collecting–Movable Pallet–Servo Movable Punching–Movable Pallet–CNC Bending–Hydraulic Cutting–Receive Table

4. Machine Pictures:

5. Machine Details :

| Description | ||

| Production name | Silo stiffener equipment | |

| Machine floor area | About 25.5m*2m(L*W) | |

| Feeding direction | left in, and right out | |

| Voltage parameter | 380v,50Hz, 3 phase | |

| Hydraulic oil | 46# hydraulic oil | |

| Gear oil | 18# hyperbolic gear oil | |

| Shaft diameter | 120mm | |

| Shaft Material | 40Cr, quenching and tempering | |

| Rack | Gantry type (Memorial archway type) | |

| Rack material | Nodular cast iron | |

| Punching die material | SKD11 | |

| Rack quantity | 18 rows | |

| Drive mode | Gear box drive | |

| Working speed | about 1 piece/min | |

| Transmission mode | Each rack with a gear distribution box drive | |

| Forming roller | GCr15, quenching, the hardness of HRC56-62 º | |

| Motor power | 45 KW *2 Siemens brand | |

| Machine color | Machine base | As required |

| Rack and gear box | As required | |

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

8.Transaction history :

Product detail pictures:

Related Product Guide:

We always follow the principle "Quality Very first, Prestige Supreme". We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for Best quality Corrugated Board Production Line - Grain bin silo leg making machine – Thomas , The product will supply to all over the world, such as: Belgium, Bangladesh, Mecca, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a in depth mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.