Factory making Silo Corrugated Sheet Processing Equipment - Steel helically corrugated pipe machine – Thomas

Factory making Silo Corrugated Sheet Processing Equipment - Steel helically corrugated pipe machine – Thomas Detail:

Metal Spiral culvert pipe machine : With the Thomas system, you can change the steel coil into different corrugation of metal corrugated pipes and meet the vast array of market demands. This includes such uses as highway and railway drainage pipes, and storm sewer pipes and bridge replacements pipe. Thomas gives you the most versatility to maximize your success. Large corrugated lockseam pipe machine can manufacture different diameters as per request. Metal corrugated pipe mill includes : Hydraulic decoiler, feeding system , roll forming , pipe forming system, Automatic Cut-Off system, Runout and Dump System .

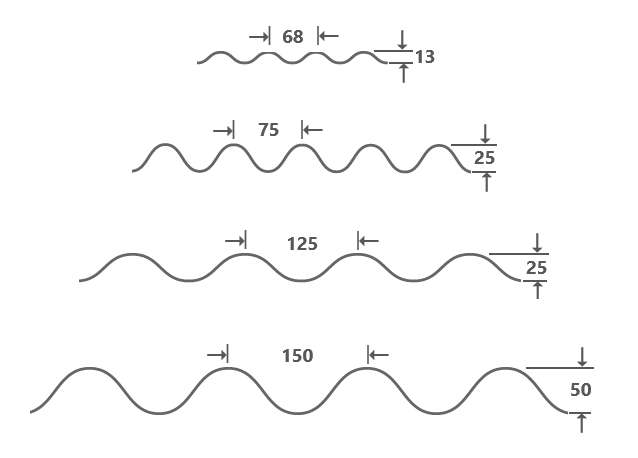

1.Drawing of the profile :

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

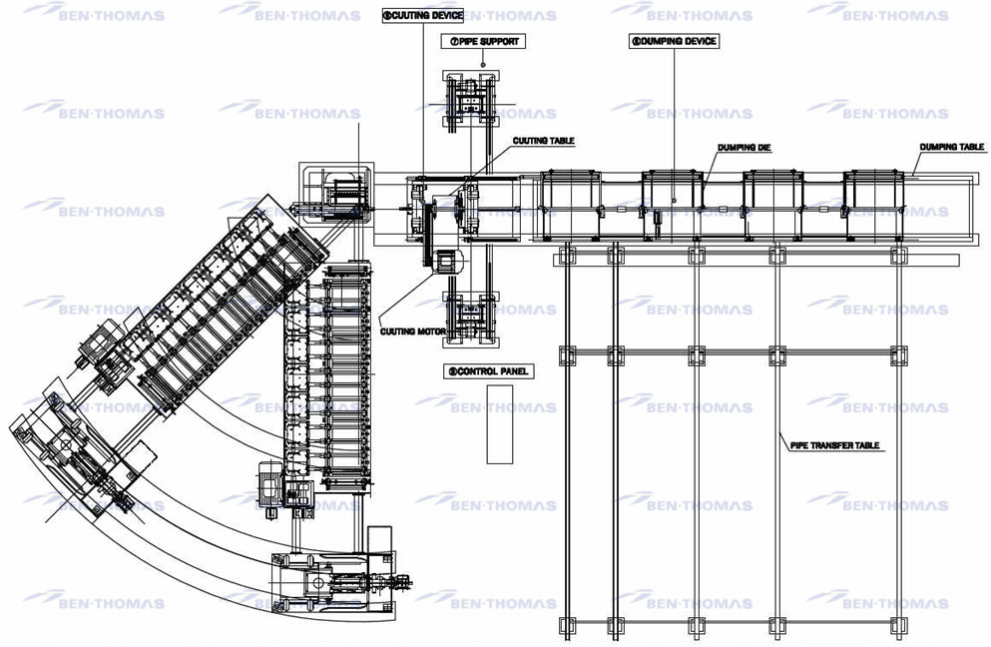

3.Working process of the production line:

Hydraulic uncoiler – Cutting – Feeding – Corrugated coil forming – Pipe forming – Cutting — Receiving table

4. Machine Pictures:

5. Machine Details :

| Description | ||

| Production name | Silo Panel Forming Machine | |

| Machine floor area | About 25.5m*2m(L*W) | |

| Feeding direction | left in, and right out | |

| Voltage parameter | 380v,50Hz, 3 phase | |

| Hydraulic oil | 46# hydraulic oil | |

| Gear oil | 18# hyperbolic gear oil | |

| Shaft diameter | 140mm | |

| Shaft Material | 40Cr, quenching and tempering | |

| Rack | Gantry type (Memorial archway type) | |

| Rack material | Nodular cast iron | |

| Punching die material | SKD11 | |

| Rack quantity | 22 rows | |

| Drive mode | Gear box drive | |

| Working speed | about 1 piece/min | |

| Transmission mode | Each rack with a gear distribution box drive | |

| Forming roller | GCr15, quenching, the hardness of HRC56-62 º | |

| Motor power | 45 KW *2 Siemens brand | |

| Machine color | Machine base | As required |

| Rack and gear box | As required | |

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

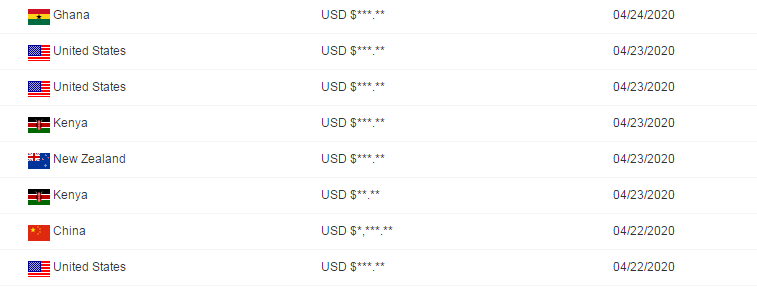

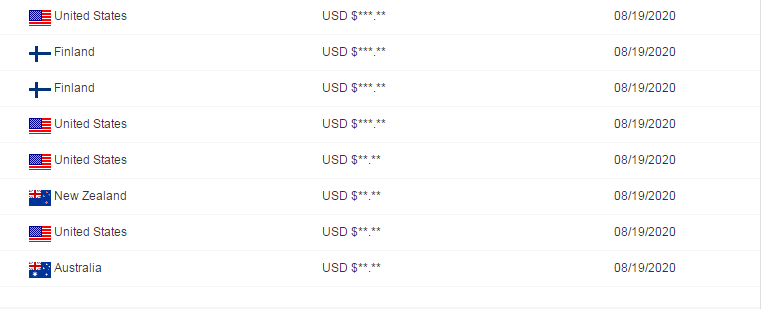

8.Transaction history :

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory making Silo Corrugated Sheet Processing Equipment - Steel helically corrugated pipe machine – Thomas , The product will supply to all over the world, such as: Comoros, Florida, Slovakia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.