High Quality Metal Culvert Pipe Production Line – Metal Spiral Corrugated Pipe Machine – Thomas

High Quality Metal Culvert Pipe Production Line – Metal Spiral Corrugated Pipe Machine – Thomas Detail:

Spiral corrugated pipes, as the best combination of strength and hydraulic efficiency, feature helical pattern and lock-seam construction in round shapes with different diameters. They are manufactured from quality galvanized corrugated sheet using advanced manufacturing technology. Meanwhile, spiral corrugated pipes can be connected by coupling systems or flange plates according to the project requirements.

Metal corrugated pipe has widely applications:

Drain system.

Culverts.

Small bridges.

Storm water detention.

Gas pipeline protection tube.

Underground cable protection.

Underpasses.

Passages for wildlife.

Coalmine vent pipes.

Well casing pipes.

Cisterns.

Agricultural irrigation.

Municipal engineering.

Storm sewer, etc.

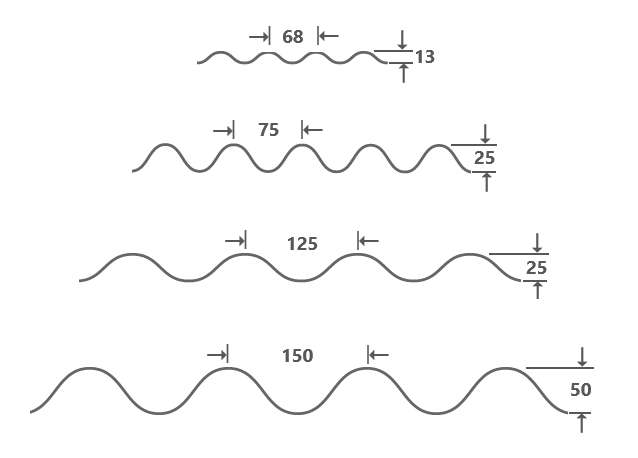

Our CMP machine can form the pipes with corrugations : 68mm × 13mm (2-2/3″ × 1/2″);

75mm × 25mm (3″ × “); 125mm × 25mm (5″ × 1″). 150*50mm

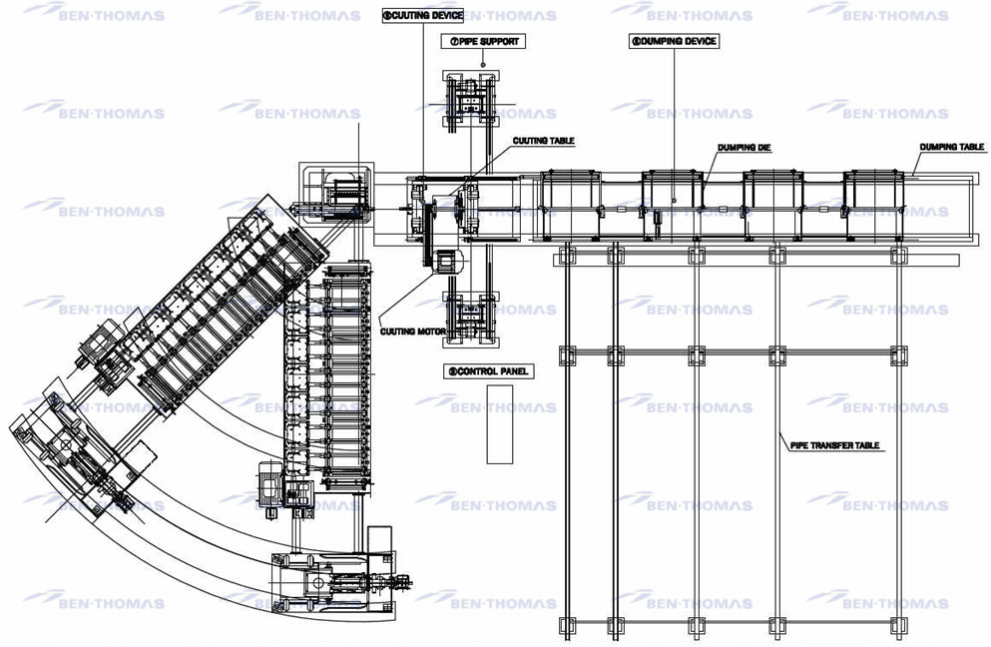

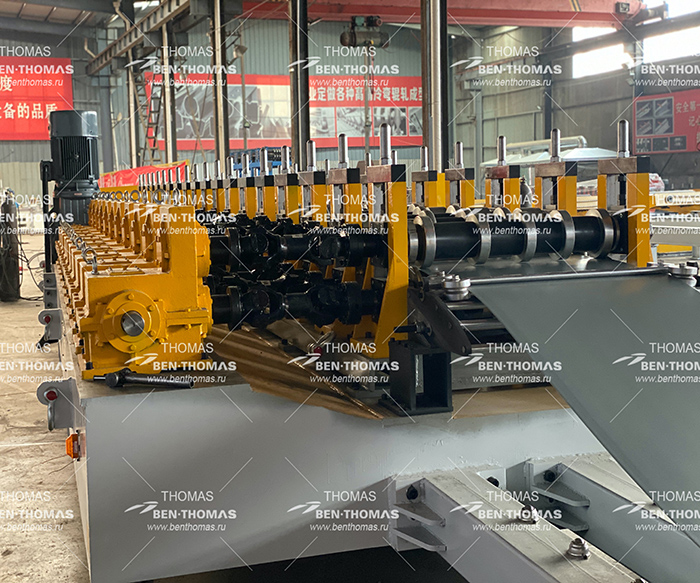

Whole production line contains parts from decoiler , corrugations forming, pipe making, pipe cutting, pipe receiving.

1.Drawing of the profile :

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

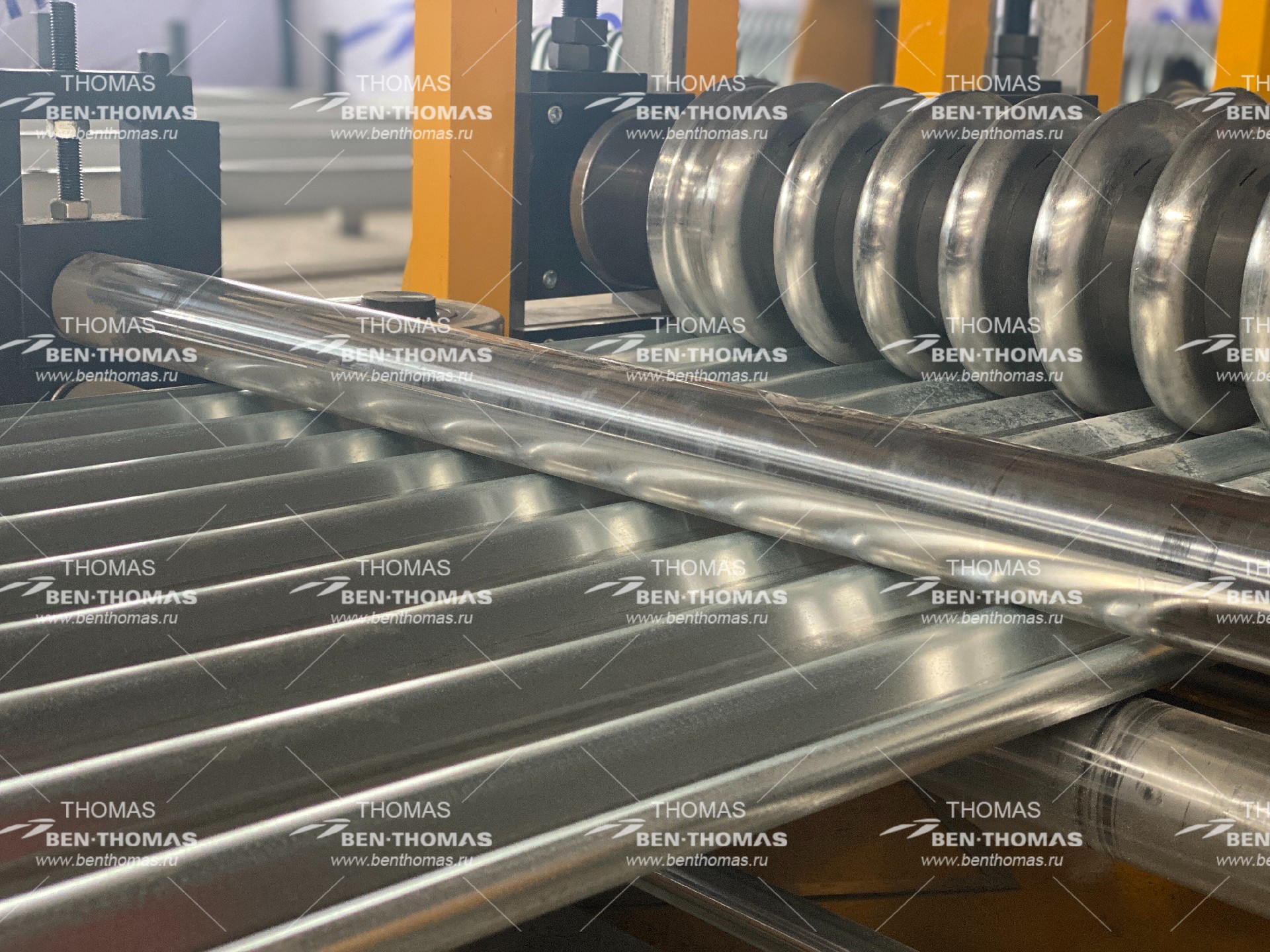

2.Finished Product:

3.Working process of the production line:

Hydraulic uncoiler – Cutting – Feeding – Corrugated coil forming – Pipe forming – Cutting — Receiving table

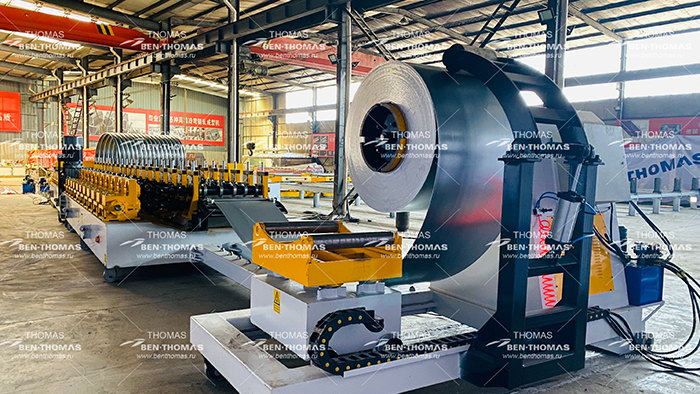

4. Machine Pictures:

5. Machine Details :

|

Description |

||

|

Production name |

Silo Panel Forming Machine |

|

|

Machine floor area |

About 25.5m*2m(L*W) |

|

|

Feeding direction |

left in, and right out |

|

|

Voltage parameter |

380v,50Hz, 3 phase |

|

|

Hydraulic oil |

46# hydraulic oil |

|

|

Gear oil |

18# hyperbolic gear oil |

|

|

Shaft diameter |

140mm |

|

|

Shaft Material |

40Cr, quenching and tempering |

|

|

Rack |

Gantry type (Memorial archway type) |

|

|

Rack material |

Nodular cast iron |

|

|

Punching die material |

SKD11 |

|

|

Rack quantity |

22 rows |

|

|

Drive mode |

Gear box drive |

|

|

Working speed |

about 1 piece/min |

|

|

Transmission mode |

Each rack with a gear distribution box drive |

|

|

Forming roller |

GCr15, quenching, the hardness of HRC56-62 º |

|

|

Motor power |

45 KW *2 Siemens brand |

|

|

Machine color |

Machine base |

As required |

|

Rack and gear box |

As required |

|

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

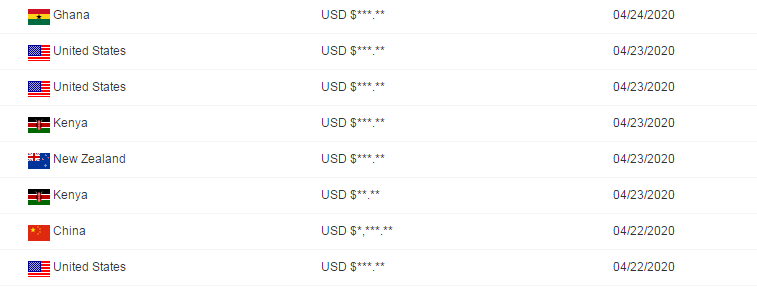

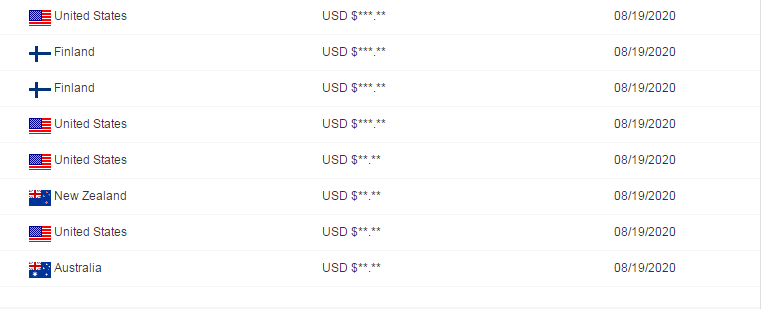

8.Transaction history :

Product detail pictures:

Related Product Guide:

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for High Quality Metal Culvert Pipe Production Line – Metal Spiral Corrugated Pipe Machine – Thomas , The product will supply to all over the world, such as: Cairo, Colombia, Albania, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!