Original Factory Feed Tower Corrugated Plate Machine - Grain silo body corrugated sheet making machine – Thomas

Original Factory Feed Tower Corrugated Plate Machine - Grain silo body corrugated sheet making machine – Thomas Detail:

Silo corrugated panel machines have been recognized for their robust design, a variety of pre or post cut options, mechanical or hydraulic press system designs. They are reliable and accurate. Available destacking, stacking, and curving also make them extremely flexible. The whole silo line is about 120Tons . More details please see below :

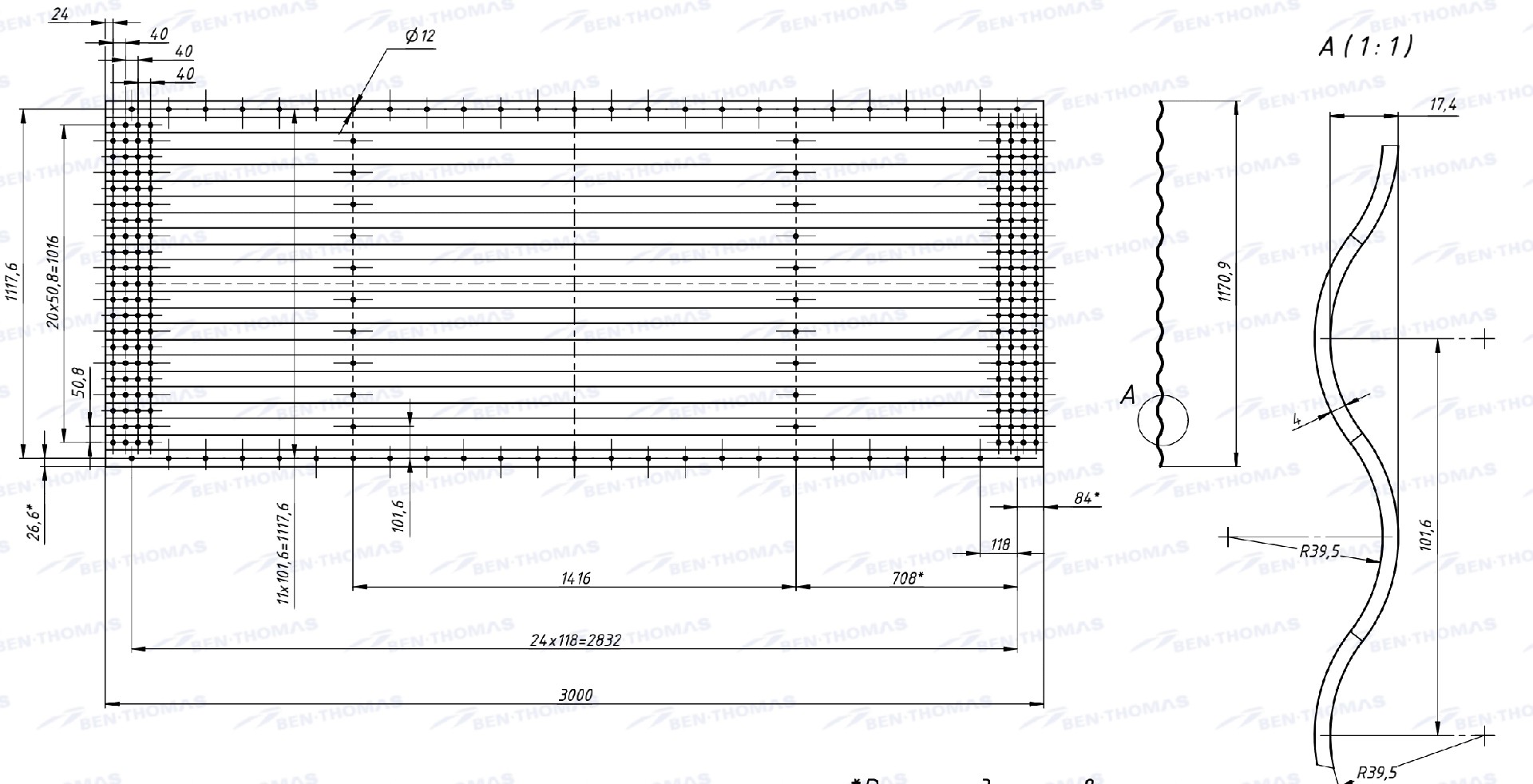

1.Drawing of the profile of the silo corrugated panel:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

3.Working process of the production line:

Hydraulic decoiler –Shovel head device(Auxiliary feeding +Leveling) –Pre Cutting–Roll Forming Machine–Slitting & Waste Wire Collecting–Movable Pallet–Servo Movable Punching–Movable Pallet–CNC Bending–Hydraulic Cutting–Receive Table

4. Machine Pictures:

5. Machine Details :

| Item No. | Equipment name | Equipment models and specifications | Quantity |

| 1 | Hydraulic decoiler with feeding car | 15 tons | 1 set |

| 2 | Auxiliary feeding +Leveling | According to final design | 1 set |

| 3 | Pre cutting | Hydraulic | 1 set |

| 4 | Roll forming machine | Automatic thickness adjustment | 1 set |

| 5 | Slitting | Automatic wire collection | 1 set |

| 6 | Movable pallet | Movable | 1 set |

| 7 | Punching device | Mechanical punch | 1 set |

| 8 | Bending | Servo Motor | 1 set |

| 9 | Cutting | Hydraulic | 1 set |

| 10 | Electrical control system | PLC: Siemens ; Converter: Siemens;Screen: Siemens; Encounter: Omoron

Electric switch :Schneider, |

1 set |

| 11 | Motor for main roll forming machine | 45KW , Siemens /Siemens BEIDE | 2 sets |

| 12 | Hydraulic pump station | 45KW | 1 set |

| 13 | Receive table | According to final design | 1 set |

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

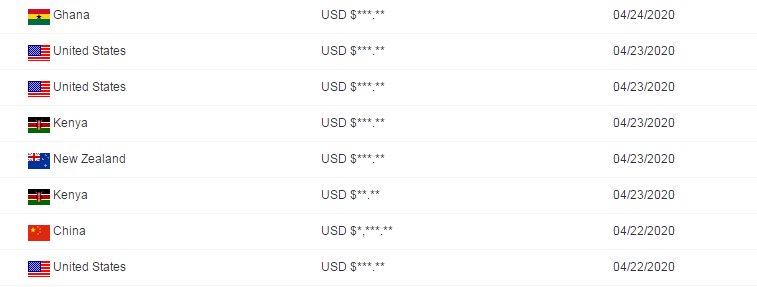

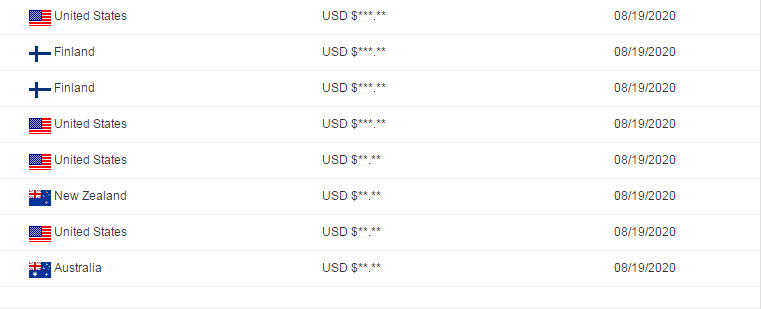

8.Transaction history :

Product detail pictures:

Related Product Guide:

It truly is a great way to improve our merchandise and repair. Our mission should be to create imaginative products to prospects with a excellent knowledge for Original Factory Feed Tower Corrugated Plate Machine - Grain silo body corrugated sheet making machine – Thomas , The product will supply to all over the world, such as: Florence, Wellington, UK, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.