Professional China Steel Corrugated Board Equipment - Grain silo body corrugated sheet making machine – Thomas

Professional China Steel Corrugated Board Equipment - Grain silo body corrugated sheet making machine – Thomas Detail:

Silo corrugated panel machines have been recognized for their robust design, a variety of pre or post cut options, mechanical or hydraulic press system designs. They are reliable and accurate. Available destacking, stacking, and curving also make them extremely flexible. The whole silo line is about 120Tons . More details please see below :

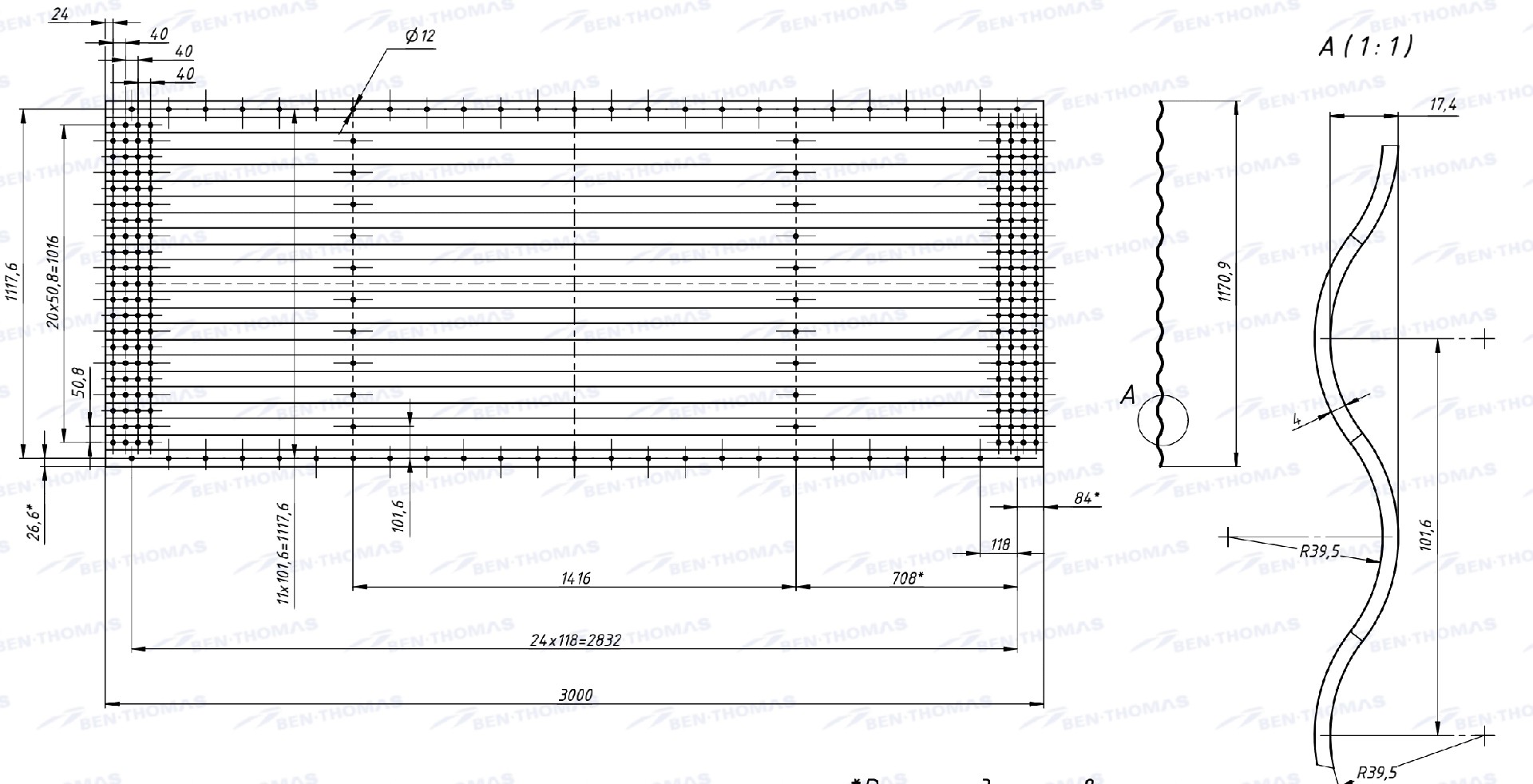

1.Drawing of the profile of the silo corrugated panel:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

3.Working process of the production line:

Hydraulic decoiler –Shovel head device(Auxiliary feeding +Leveling) –Pre Cutting–Roll Forming Machine–Slitting & Waste Wire Collecting–Movable Pallet–Servo Movable Punching–Movable Pallet–CNC Bending–Hydraulic Cutting–Receive Table

4. Machine Pictures:

5. Machine Details :

| Item No. | Equipment name | Equipment models and specifications | Quantity |

| 1 | Hydraulic decoiler with feeding car | 15 tons | 1 set |

| 2 | Auxiliary feeding +Leveling | According to final design | 1 set |

| 3 | Pre cutting | Hydraulic | 1 set |

| 4 | Roll forming machine | Automatic thickness adjustment | 1 set |

| 5 | Slitting | Automatic wire collection | 1 set |

| 6 | Movable pallet | Movable | 1 set |

| 7 | Punching device | Mechanical punch | 1 set |

| 8 | Bending | Servo Motor | 1 set |

| 9 | Cutting | Hydraulic | 1 set |

| 10 | Electrical control system | PLC: Siemens ; Converter: Siemens;Screen: Siemens; Encounter: Omoron

Electric switch :Schneider, |

1 set |

| 11 | Motor for main roll forming machine | 45KW , Siemens /Siemens BEIDE | 2 sets |

| 12 | Hydraulic pump station | 45KW | 1 set |

| 13 | Receive table | According to final design | 1 set |

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

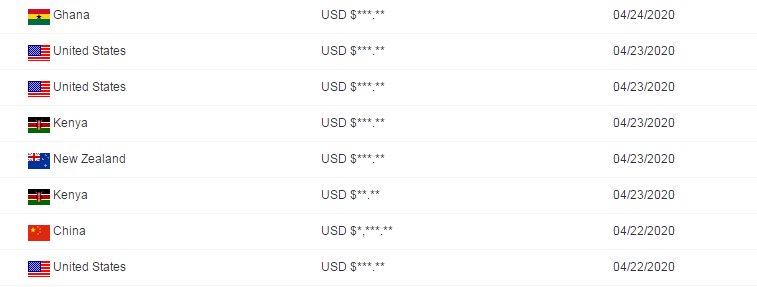

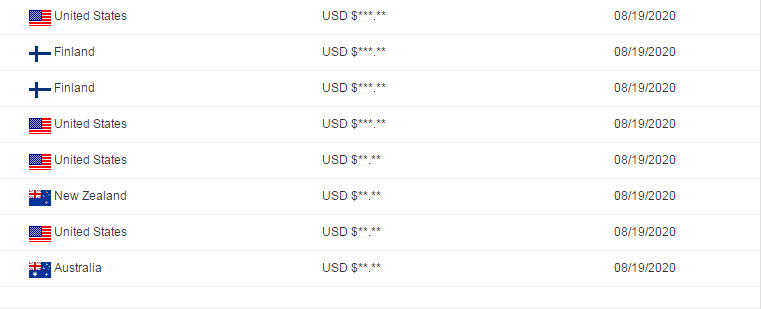

8.Transaction history :

Product detail pictures:

Related Product Guide:

With this motto in mind, we've turn into one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Professional China Steel Corrugated Board Equipment - Grain silo body corrugated sheet making machine – Thomas , The product will supply to all over the world, such as: Sri Lanka, Birmingham, Serbia, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.