Special Design for Granary Corrugated Board Equipment - Grain Bin Silo top panel production line – Thomas

Special Design for Granary Corrugated Board Equipment - Grain Bin Silo top panel production line – Thomas Detail:

Silo cap machines : Nowadays in the world , grain storage bin space demands is increasing, and the demand for silo tanks is rising as well. Our silo roof production lines are in need to meet the growing demand. We offer fully automatic systems to produce the finished silo roofs, which includes decoiler, feeding, cutting, roll forming, punching, receiving.

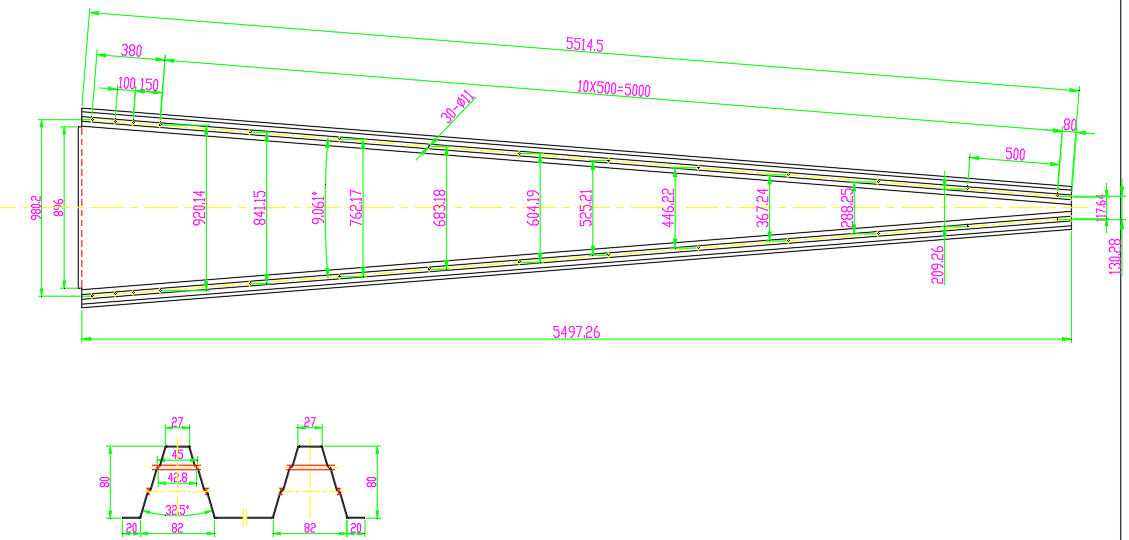

1. Silo Roof Profile Drawing:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only .)

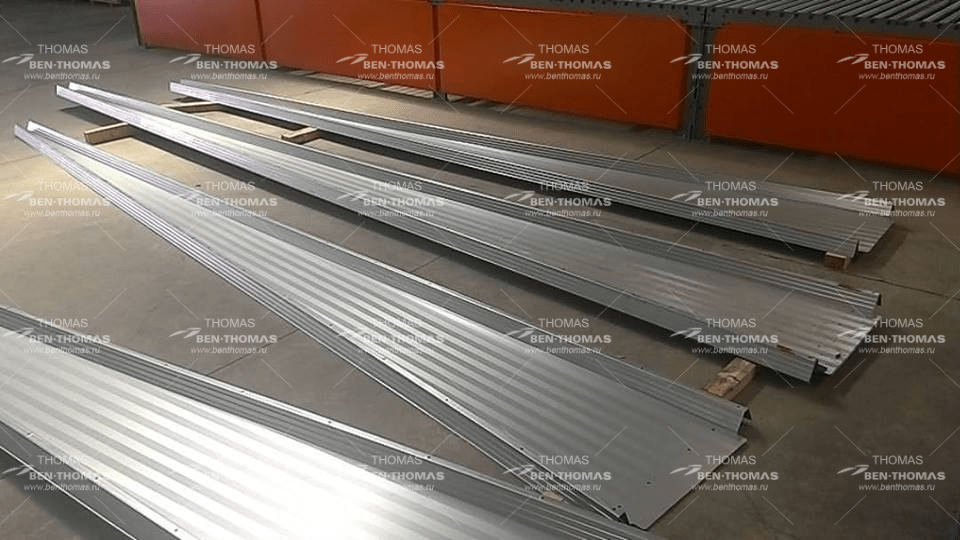

2.Finished Product:

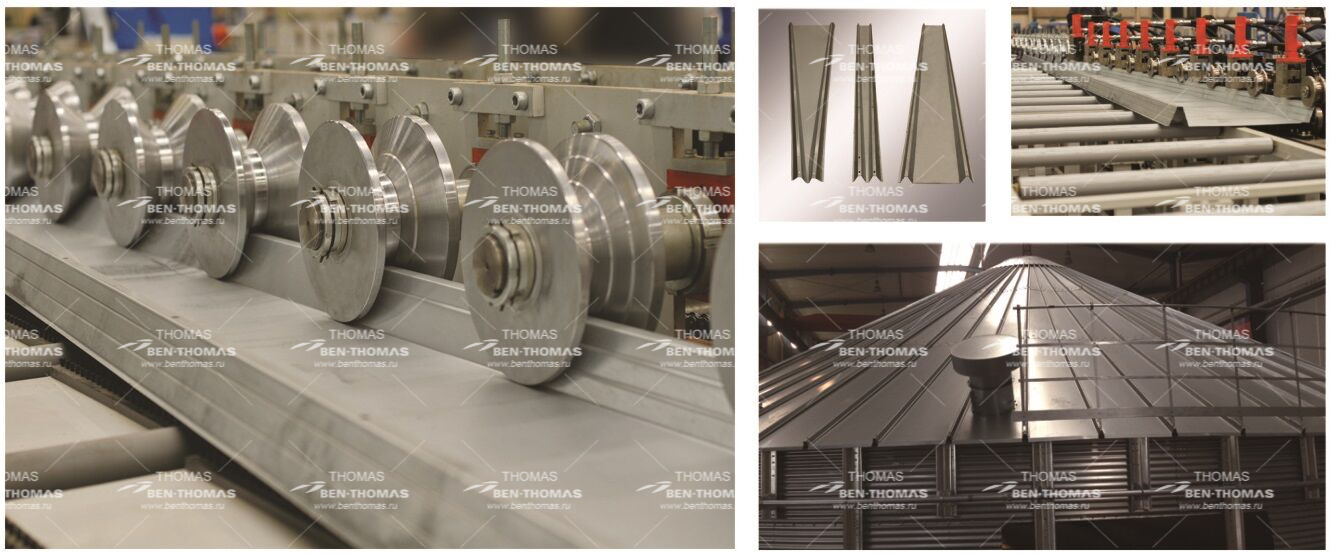

3.Working process of the production line:

Decoiler—leveling—cutting with angle —servo displacement rolling shear—double layer conveying roller table—single layer conveying roller table —pneumatic pressing—CNC servo punching 1#—roll forming machine 1#—conveying roller table —CNC servo punching 2#—rolling forming machine 2#—conveying roller table—pneumatic suction and palletizing

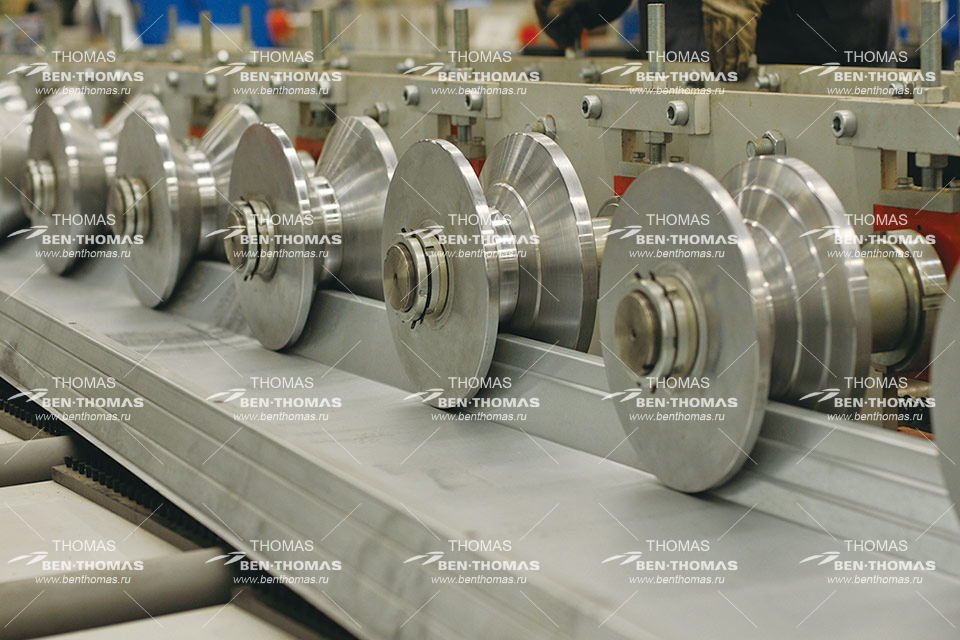

4. Machine Pictures:

5. Machine Details :

|

No |

Name |

Number |

|

1 |

10 tons hydraulic automatic decoiler (with feeding trolley) |

1 set |

|

2 |

Leveling machine |

1 set |

|

3 |

Angle cutting machine |

1 set |

|

4 |

Servo displacement rolling shear (with pinch roller) |

1 set |

|

5 |

10m double-layer conveyor roller table (equipped with stopper, turn over, guide device) |

1 set |

|

6 |

8m single-layer conveyor roller (with guide positioning) |

1 set |

|

7 |

Double-station angle punching machine (including cutting small head waste) |

2 set |

|

8 |

8m conveying roller table (with guiding positioning, pneumatic pressing and feeding device) |

1 set |

|

9 |

Roll forming part 1# |

1 set |

|

10 |

CNC servo punching machine 1# |

1 set |

|

11 |

15m conveyor roller |

1 set |

|

12 |

8m conveying roller table (with guiding positioning, pneumatic pressing and feeding device) |

1 set |

|

13 |

CNC servo punching machine 2# |

1 set |

|

14 |

Roll forming part 2# |

1 set |

|

15 |

15m conveyor roller platform |

1 set |

|

16 |

8m conveyor roller platform (with guide and positioning device) |

1 set |

|

17 |

Automatic palletizer |

1 set |

|

18 |

Electric control system |

1 set |

|

19 |

Pneumatic system |

1 set |

|

20 |

Hydraulic system |

1 set |

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

8.Transaction history :

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Special Design for Granary Corrugated Board Equipment - Grain Bin Silo top panel production line – Thomas , The product will supply to all over the world, such as: Germany, Croatia, Rwanda, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.