Well-designed Galvanized Corrugated Panel Forming Machine - Grain bin silo stiffener making machine – Thomas

Well-designed Galvanized Corrugated Panel Forming Machine - Grain bin silo stiffener making machine – Thomas Detail:

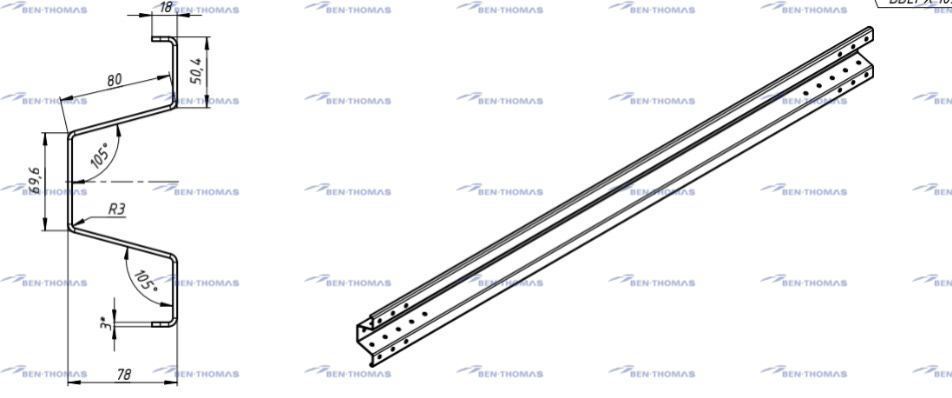

1.Drawing of the profile of the silo stiffener:

(Machine can be customized according to your needs, the following picture is the drawing provided by our customer, for reference only.)

2.Finished Product:

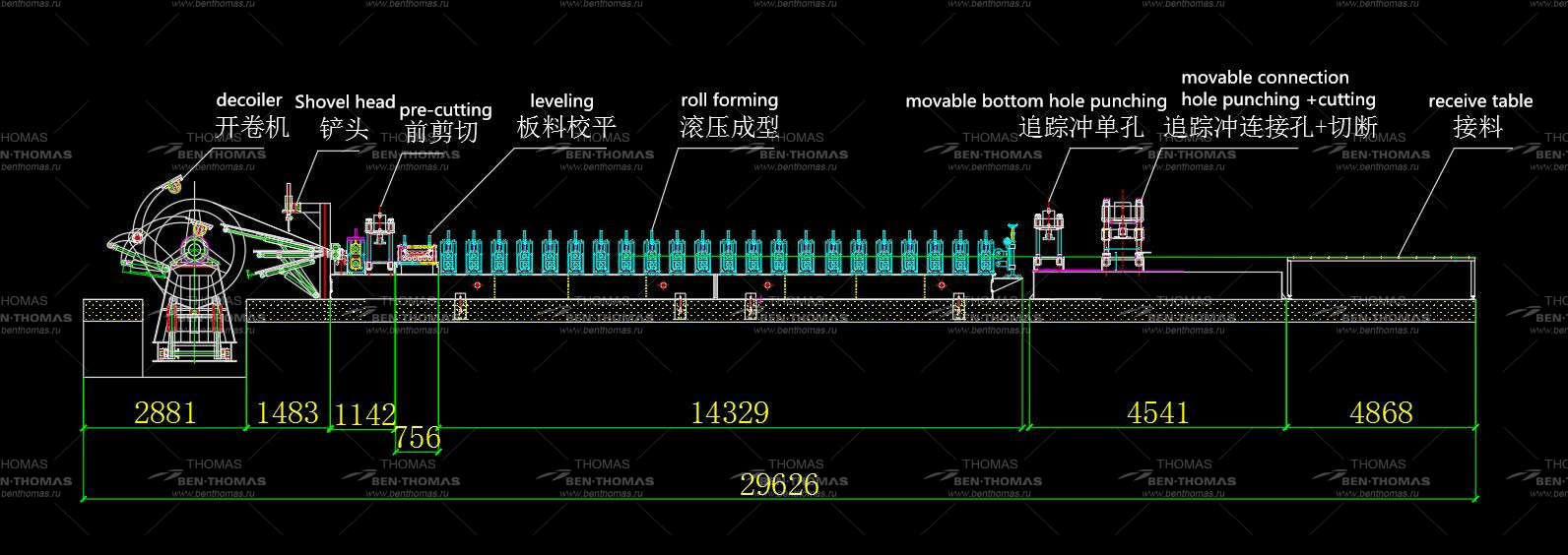

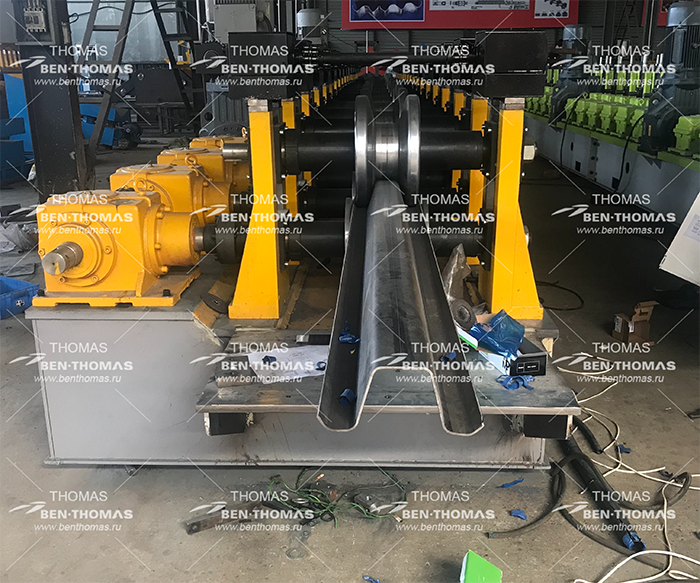

3.Working process of the production line:

Hydraulic unwinder —– Shovel device (auxiliary feed + leveling) —– Pre-cutting – Main forming machine —– Telescopic support – Hydraulic punching device – Moving pallet —– CNC bending Hydraulic – Hydraulic cutting – receiving table

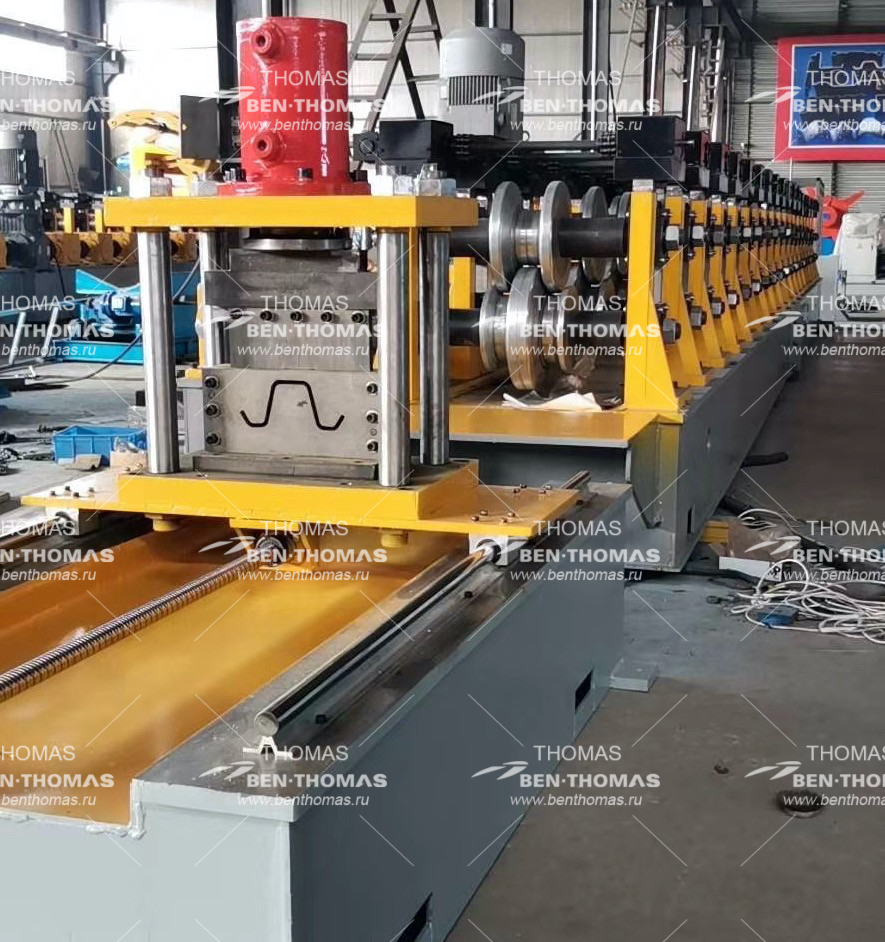

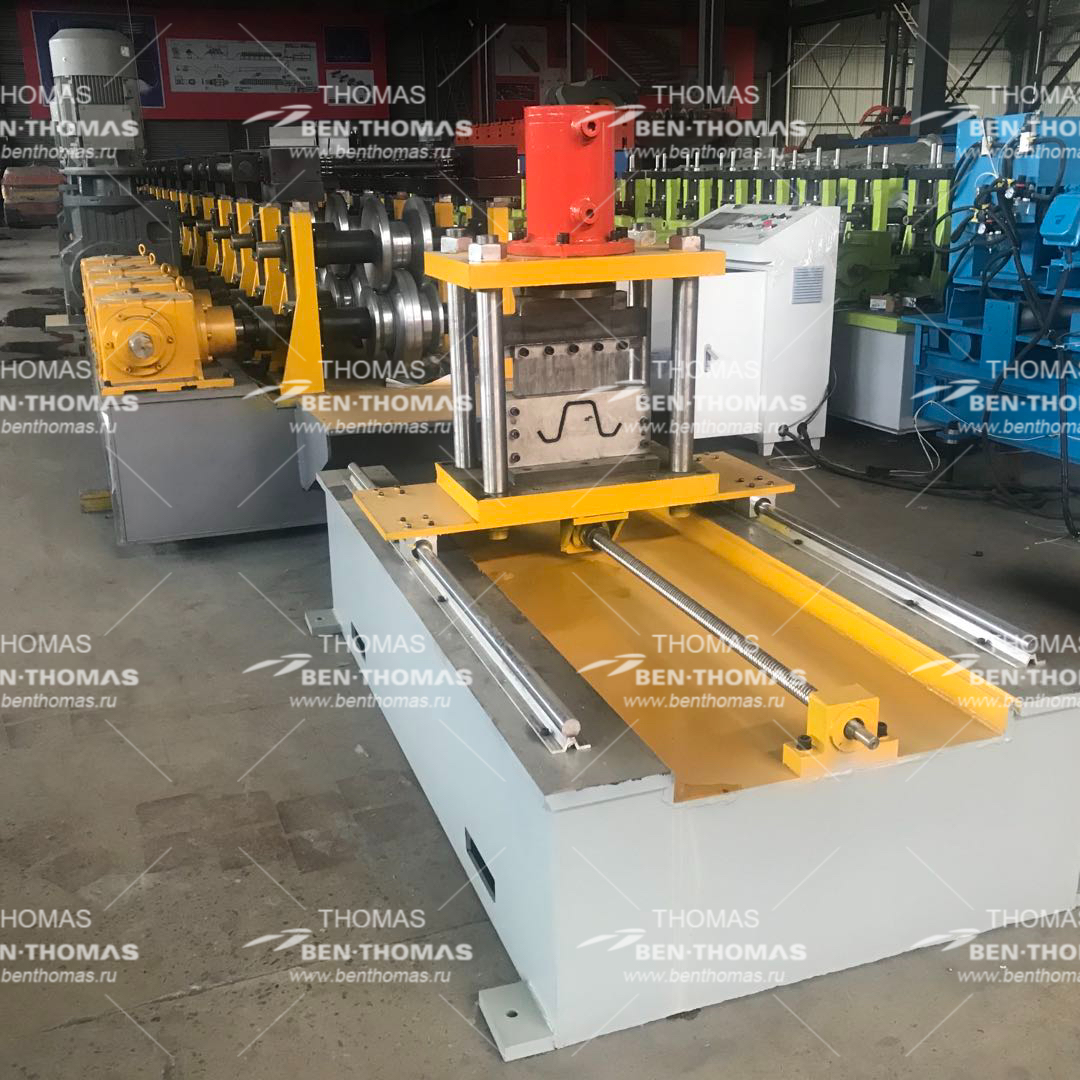

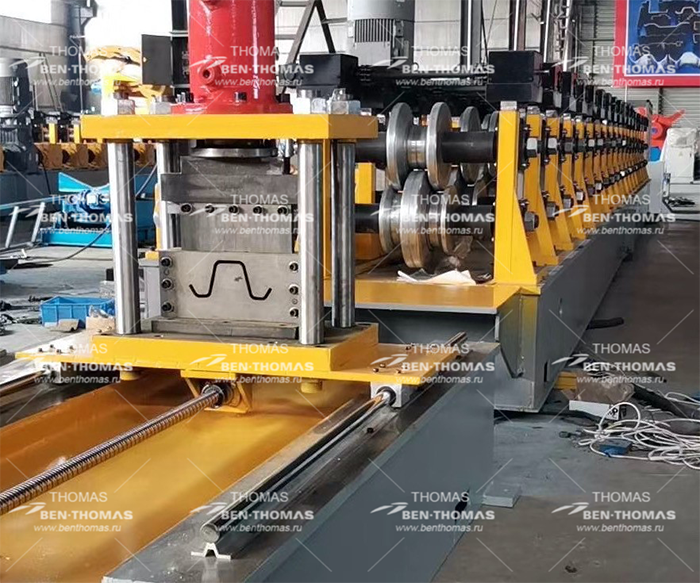

4. Machine Pictures:

5. Machine Details :

|

Description |

||

|

Production name |

Silo Stiffener Forming Machine |

|

|

Machine floor area |

About 25.5m*2m(L*W) |

|

|

Feeding direction |

left in, and right out |

|

|

Voltage parameter |

380v,50Hz, 3 phase |

|

|

Hydraulic oil |

46# hydraulic oil |

|

|

Gear oil |

18# hyperbolic gear oil |

|

|

Shaft diameter |

120mm |

|

|

Shaft Material |

40Cr, quenching and tempering |

|

|

Rack |

Gantry type (Memorial archway type) |

|

|

Rack material |

Nodular cast iron |

|

|

Punching die material |

SKD11 |

|

|

Rack quantity |

18 rows |

|

|

Drive mode |

Gear box drive |

|

|

Working speed |

about 1 piece/min |

|

|

Transmission mode |

Each rack with a gear distribution box drive |

|

|

Forming roller |

GCr15, quenching, the hardness of HRC56-62 º |

|

|

Motor power |

45 KW *2 Siemens brand |

|

|

Machine color |

Machine base |

As required |

|

Rack and gear box |

As required |

|

6. After-sales service :

1) . User manuals / videos on installation, adjustment, setup and maintenance of the machine will be provided.

2). The machine is with Wi-Fi function, our technicians will help to work if the machine has a problem.

3). when the borders are open, we will send technicians to your factory for training. (The cost is paid by the seller.)

4). Warranty 2 years (Excluding man-made damage)

5). Delivery time: 90 working days.

6). Machine price: contact us.

7.About Us :

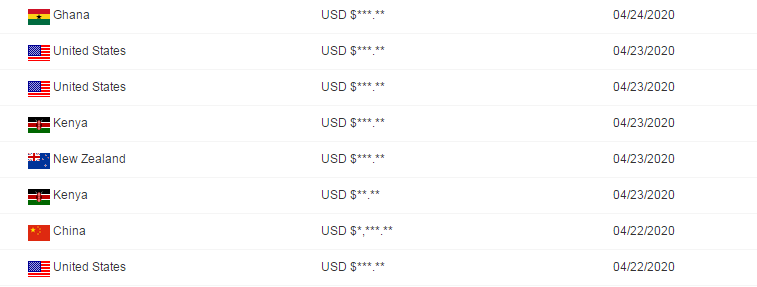

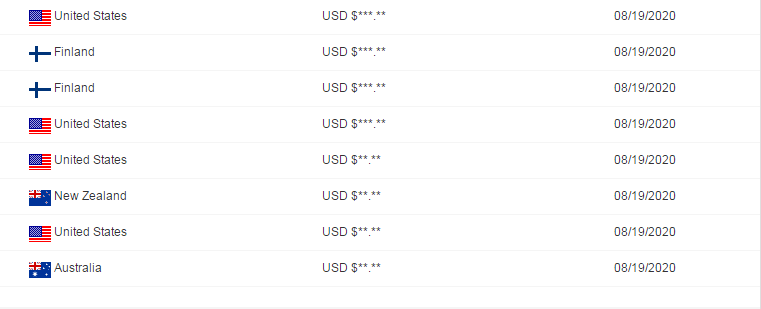

8.Transaction history :

Product detail pictures:

Related Product Guide:

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for Well-designed Galvanized Corrugated Panel Forming Machine - Grain bin silo stiffener making machine – Thomas , The product will supply to all over the world, such as: Poland, South Korea, Thailand, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.